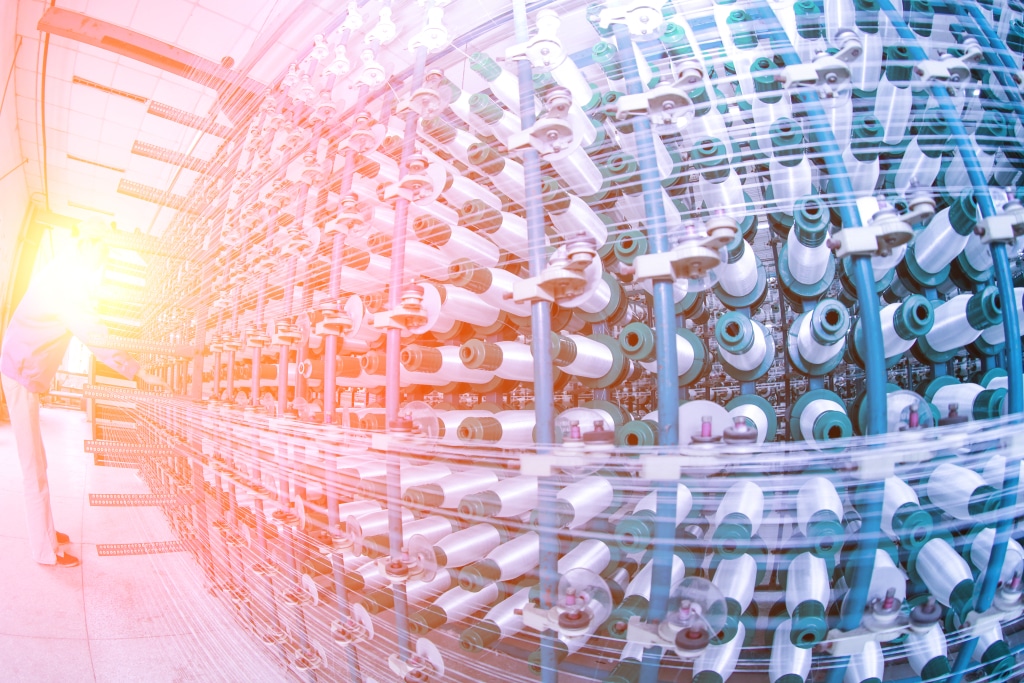

Production sites worldwide

Turning an Energy Crisis into a €350 Million Opportunity

When energy costs surged fivefold across Europe, this global chemicals leader faced the potential shutdown of critical operations. Together, partner DB Energy and EFESO worked with the company’s in-house team to conduct rapid diagnostics across 11 production sites. The partnership identified 160 energy-saving opportunities, transforming an existential threat into sustainable operational advantage.

Our Client

A diversified chemicals group operating globally with both specialty chemicals and commodity products portfolios. The company maintains a strong culture of operational excellence developed through long-standing continuous improvement initiatives. Its European operations represent critical production capacity for both regional and global markets, with heavy energy consumption integral to its manufacturing processes.

Operations in Europe

Employees at largest site

Site coverage area

The Challenge

The war in Ukraine created an unprecedented energy crisis that threatened the viability of European chemical manufacturing operations.

- Fivefold cost increase: Energy prices in Europe rose dramatically due to the disruption of Russian gas supplies, creating immediate pressure on heavy energy-consuming production units

- Existential threat to European operations: The sudden cost surge posed the risk of potential shutdown for business units across multiple European countries, threatening both regional supply chains and global production capacity

- Complex energy infrastructure: The interconnected nature of production units with centralized energy departments required comprehensive analysis across multiple sites, to identify savings opportunities while maintaining operational continuity

Real Results Achieved Together

Comprehensive energy diagnostics transformed an immediate crisis into a structured improvement program across European operations. Working alongside site teams and engineering departments, the partnership delivered immediate relief through quick wins and long-term sustainability through major energy projects.

Total savings identified

Energy-saving ideas generated

CO2 emissions reduction

Quick win initiatives

Transformation Impact

- Implemented high-CapEx projects including steam condensate recovery and cogeneration plant turbine upgrades

- Achieved immediate cost relief through operational adjustments requiring minimal investment

- Enabled client's engineering department to continue with concept designs and diagnostics independently

Our Approach

The partnership combined EFESO’s operational excellence expertise with DB Energy’s specialized energy engineering capabilities, working closely with the in-house team.

The three-step approach began with energy walkthroughs, spending one to two days on-site analyzing energy balance and discussing findings with operators and engineers. S

elected opportunities moved to concept design phase, developing detailed feasibility studies and business cases. The engineering and construction phase followed, with projects implemented either by the client’s in-house engineering team or subcontracted to DB Energy.

Initial diagnostics at four production plants and the main energy department expanded to ten additional plants across different European countries.

The vendor-neutral engineering expertise from DB Energy enabled unbiased assessment of energy-saving opportunities, from small operational improvements to large capital expenditure projects.

Quick wins, including adjusting pump pressure levels and improving steam pipe insulation, delivered immediate savings to recover project costs rapidly.

Facing Similar Energy and Cost Challenges?

- Rising energy costs threatening your operational margins and production viability

- Transforming energy constraints into competitive advantage through systematic improvement

- Partner with us to identify and implement sustainable cost reduction opportunities