Creating a solid, structured plan for the material flow of its production and validated the static forecast, enabling the factory to increase the output with the existing machinery.

Discover how EFESO works side by side with clients across industries to achieve measurable, lasting impact. Each story captures the challenges our clients faced, the actions we took together – from boardroom to shop floor – and the tangible operational and financial results delivered.

Creating a solid, structured plan for the material flow of its production and validated the static forecast, enabling the factory to increase the output with the existing machinery.

Creating a solid, structured plan for the material flow of its production and validated the static forecast, enabling the factory to increase the output with the existing machinery.

A global technology manufacturer partnered with EFESO to gain cost transparency, identify savings opportunities, and strengthen cross-functional alignment through a comprehensive cost engineering program.

Fact-based restructuring of a complex industrial site, enabling a clear shutdown decision, cash-drain elimination, and a structured roadmap for execution.

Deployed predictive maintenance across 12 production sites, achieving 90% business case accuracy and building internal capabilities.

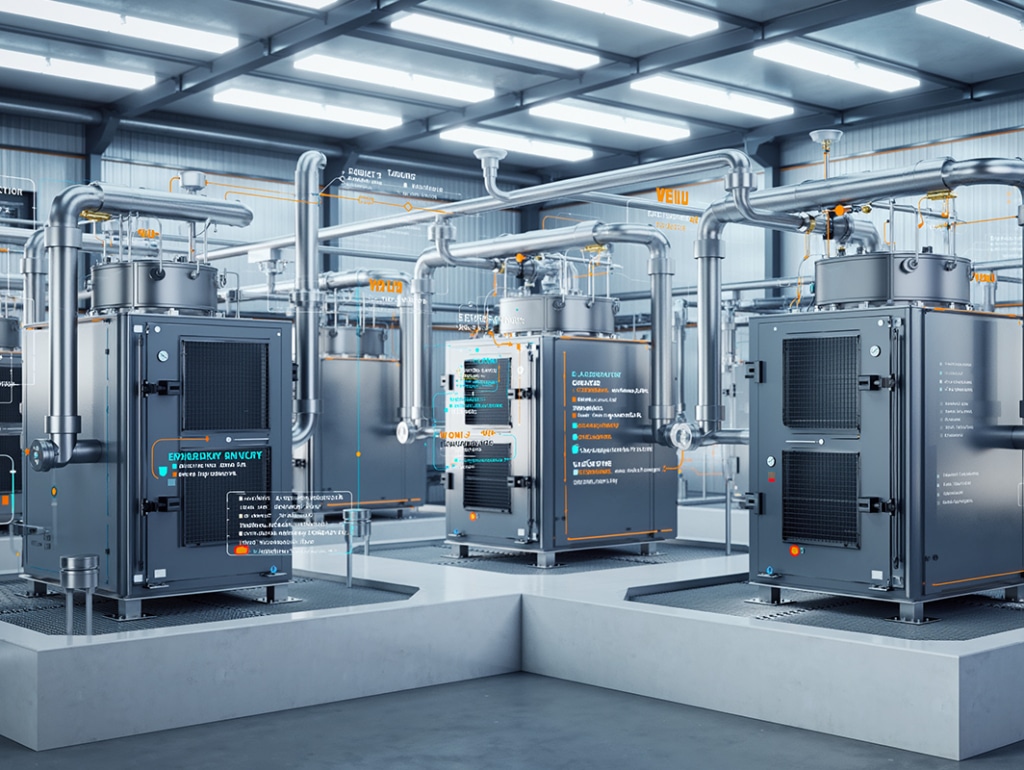

Transformed manufacturing operations for energy technology leader, doubling production output while identifying $16M EBITDA opportunities.

A scientific technology manufacturer faced a transformation that delivered sustainable cost reductions while establishing new procurement capabilities for ongoing optimization.

Packaging machinery group needed lead time and inventory optimization. We conducted comprehensive value stream analysis, identified bottlenecks, and developed transformation roadmap, targeting 40% reduction potential.

Window manufacturer required operational turnaround amid market pressures. We restructured production, implemented lean manufacturing, and optimized supply chain, reducing costs by 30%.

Following assessment, Coesia required execution of transformation program. We implemented lean processes, optimized inventory management, and reduced lead times, achieving 35% working capital reduction.

Construction equipment manufacturer required production efficiency transformation. We optimized assembly processes, implemented lean manufacturing, and enhanced supply chain coordination, increasing productivity by 30%.

Industrial cooling systems provider faced operational complexity post-acquisition. We integrated operations, standardized processes, and optimized production planning, improving delivery performance by 45%.

Scientific instruments manufacturer faced production bottlenecks and quality challenges. We redesigned manufacturing flow, implemented lean principles, and enhanced testing protocols, improving on-time delivery to 95%.

Enabled 15 SME suppliers to calculate Scope 1 and 2 emissions, establishing CO2 reduction roadmaps within six weeks.

Discover measurable outcomes achieved with our clients

See how transformation happens, from boardroom to shop floor

Let’s discuss how we can deliver similar impact for you