Integrated two pharmaceutical companies across five countries, delivering 15% operational cost synergies and 13% revenue growth.

Discover how EFESO works side by side with clients across industries to achieve measurable, lasting impact. Each story captures the challenges our clients faced, the actions we took together – from boardroom to shop floor – and the tangible operational and financial results delivered.

Integrated two pharmaceutical companies across five countries, delivering 15% operational cost synergies and 13% revenue growth.

Optimized asset portfolio across seven sites, relocating production to Mexico, achieving 4x enterprise value growth.

Transformed manufacturing operations for energy technology leader, doubling production output while identifying $16M EBITDA opportunities.

Chemical company restructured operations post-Chapter 11, implementing organizational redesign and maintenance excellence, achieving €6M annual savings.

Harmonized post-merger manufacturing cultures through customized operating system, delivering 40% cost reduction and sustainable capabilities.

Industrial machinery manufacturer faced complexity in custom equipment production. We implemented modular design principles, standardized components, and optimized project management, reducing lead times by 40%.

Food ingredients supplier required rapid turnaround after quality issues. We stabilized operations, rebuilt quality systems, and restored customer confidence, returning to full production within 6 months.

Window manufacturer required operational turnaround amid market pressures. We restructured production, implemented lean manufacturing, and optimized supply chain, reducing costs by 30%.

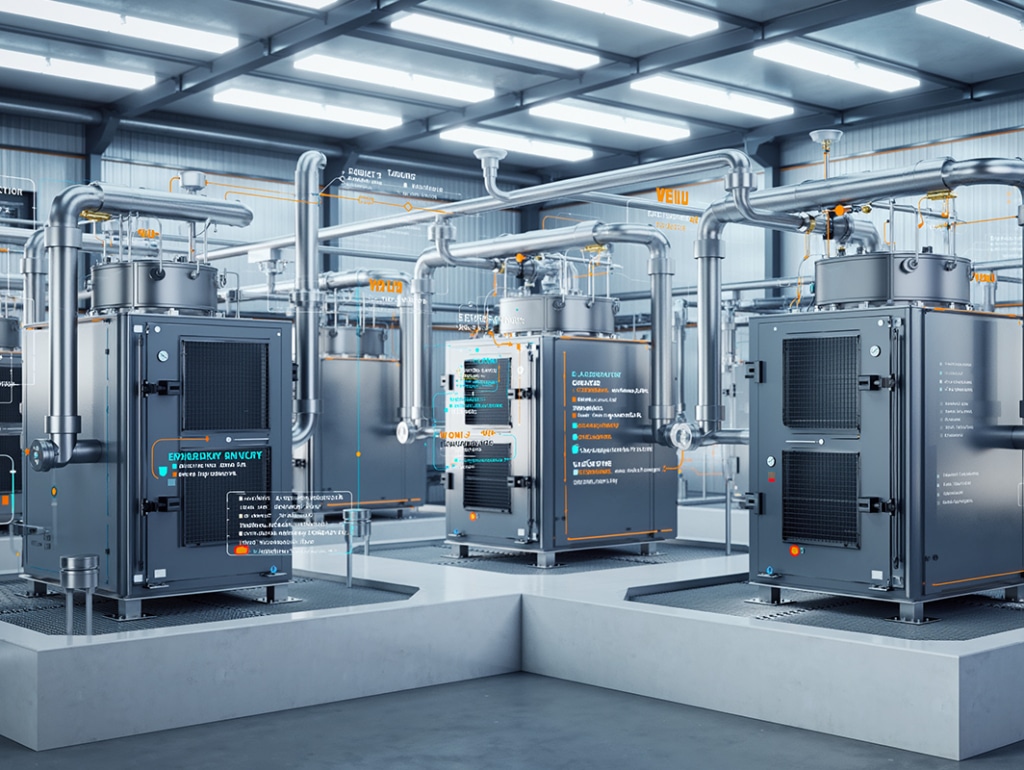

Petrochemical manufacturer needed operational excellence across multiple plants. We standardized best practices, implemented digital solutions, and optimized energy usage, reducing operating costs by 15%.

Scientific instruments manufacturer faced production bottlenecks and quality challenges. We redesigned manufacturing flow, implemented lean principles, and enhanced testing protocols, improving on-time delivery to 95%.

Energy infrastructure operator faced aging assets and rising maintenance costs. We implemented reliability-centered maintenance, optimized turnarounds, and enhanced asset management, extending equipment life by 30%.

Agricultural producer needed productivity improvement and waste reduction. We optimized growing processes, automated harvesting operations, and enhanced quality control, increasing yield by 25%.

Investment fund required battery manufacturing joint venture assessment. We conducted technical due diligence, operational analysis, and risk evaluation, identifying 35% downside risk and 15% EBITDA upside.

Operational due diligence revealed 105% Capex adjustments, enabling accurate investment sizing for bakery acquisition.

Discover measurable outcomes achieved with our clients

See how transformation happens, from boardroom to shop floor

Let’s discuss how we can deliver similar impact for you