Employees

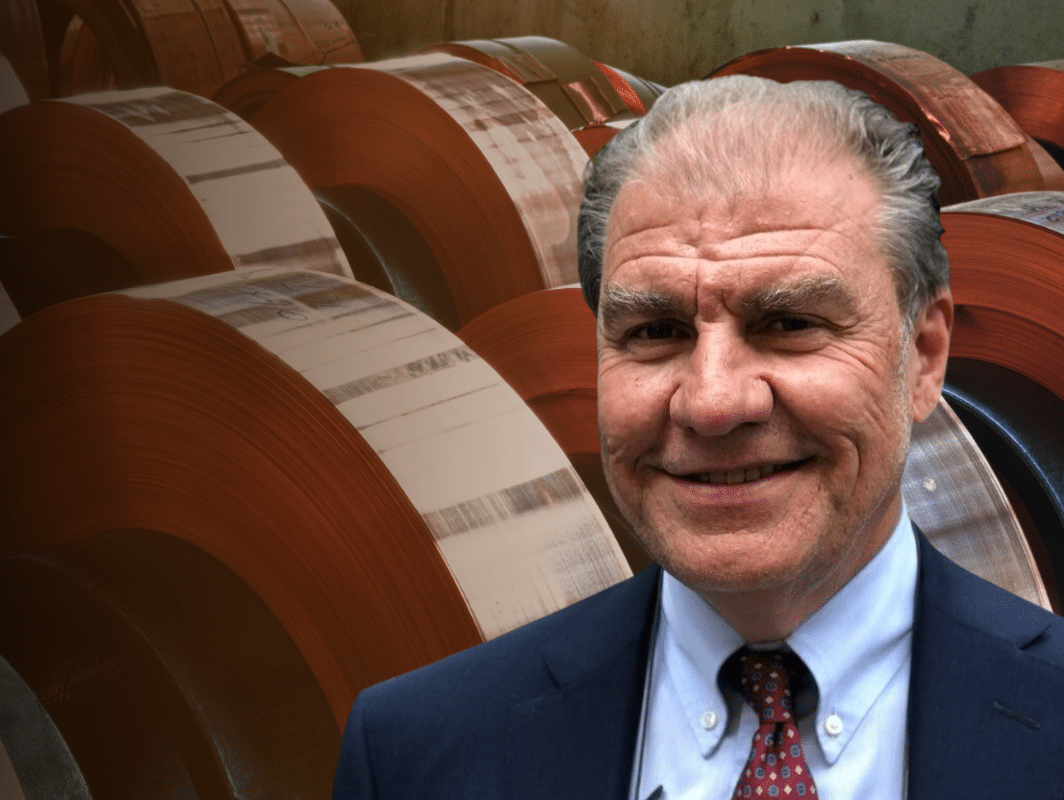

Integrated Business Planning at a Global Copper Manufacturer

EFESO partnered with KME Group, a leading global copper manufacturer, to integrate Sales & Operations Planning (S&OP) into a cohesive business process aligned with the broader supply chain. The collaboration drove strategic mindset transformation, improved on-time and in-full delivery performance, and reduced overall metal stock — generating a €100 million financial impact and enhancing cash flow predictability.

Our Client

KME Group is a leading global manufacturer of copper and copper alloy products with more than 3,000 employees, serving industries such as construction, automotive, electrical, and HVAC. With a strong international presence, KME designs, produces, and distributes high-quality rolled and extruded copper products, combining advanced manufacturing capabilities with sustainable practices to meet the needs of industrial and commercial customers worldwide

“EFESO excelled at adapting the project’s original targets to changing circumstances, addressing unexpected challenges with remarkable speed and responsiveness.

“

The Challenge

KME sought to drive a strategic transformation across its global operations through cross-functional integration and a more mature, end-to-end S&OP process. The company aimed to enhance operational alignment, improve delivery reliability, and optimize working capital management.

• Transforming the organization’s strategic mindset and fostering collaboration across functions

• Integrating S&OP into a cohesive process aligned with the overall supply chain

• Improving delivery performance and reducing metal inventory while maintaining service levels

Real Results Achieved with our Clients

The integrated business planning initiative delivered measurable operational and financial improvements across KME’s global network.

Improvement in delivery performance (OTIF)

Reduction in overall metal stock

Financial impact through enhanced cash flow and inventory efficiency

Transformation Impact

- Significantly influenced cash flow predictability

- Collaboration between departments thanks to EFESO Dashboard

- Implement operational improvements to foster efficient inflow and outflow coordination for stock management

- Improvement of Customer Service and Capital Efficiency

Our Approach

The 18-month project was structured in three key phases to ensure a sustainable transformation:

Assessment and Diagnostic (4 months)

A comprehensive organizational assessment identified structural and process improvement opportunities across the end-to-end supply chain.

Implementation (8 months)

Multiple cross-functional workstreams were launched to implement new planning, forecasting, and performance management practices.

Refinement and Optimization (6 months)

Fine-tuning of solutions and performance governance ensured lasting adoption and long-term impact.

Ready to Integrate Your Business Planning for Greater Performance?

• Transform strategic planning into actionable operational alignment.

• Reduce inventory and boost cash flow through integrated S&OP.

• Build end-to-end visibility and accountability across your organization.