Production plants

Lamb Weston / Meijer Builds Sustainable Continuous Improvement Culture

Lamb Weston / Meijer partnered with EFESO to strengthen process reliability, reduce cost price, and embed a sustainable continuous improvement culture across its two largest European plants. Through structured performance management, targeted improvement waves, and a strong Human Dynamics foundation, the teams delivered significant operational and financial impact.

Our Client

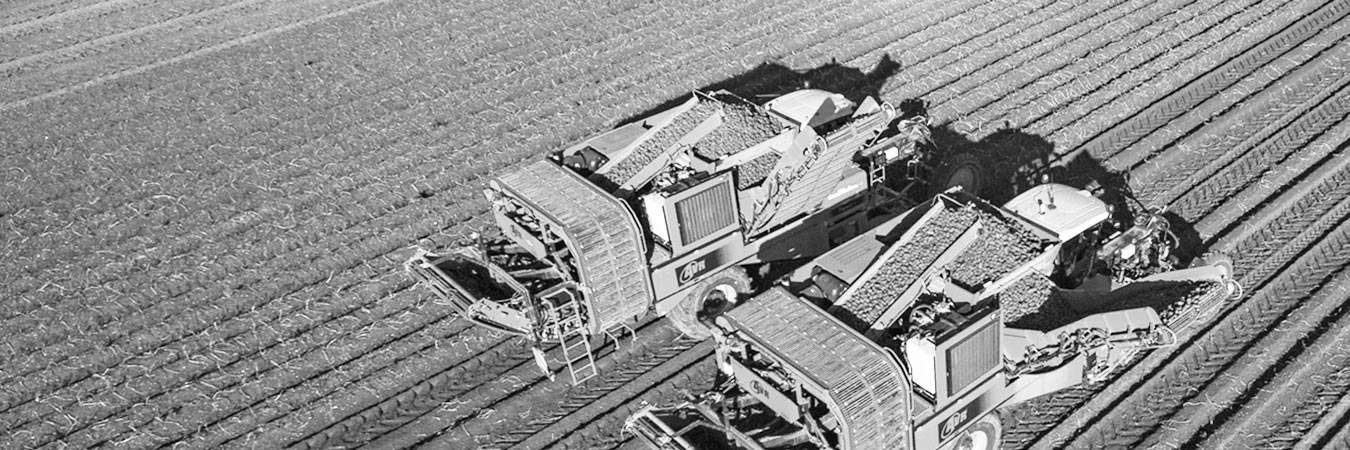

Launched in 1960, Lamb Weston® is a world leading brand in high quality potato products which are sold in over 100 countries around the world in a collaboration between Lamb Weston (US) and Lamb Weston / Meijer. Together, they make the world’s number 2 frozen potato company. The LWM company has 6 production plants in three countries.

Countries served

Major production sites

“We have chosen EFESO, because EFESO is focussed on sustainable anchoring of continuous improvement. Hereby EFESO is, in close cooperation with the plant, realizing structural performance improvement and cost control.

“

The Challenge

- Improve reliability of the production process while simultaneously reducing cost price

- Deliver a high-impact business case for the two largest European production sites

- Build and mobilize a central improvement team of young potentials

- Develop and sustain an autonomous continuous improvement culture

- Strengthen on-site capabilities while anchoring standards through a Performance Control System supported by Human Dynamics

Real Results Achieved Together

The boost program delivered significant improvements across both production sites, creating a sustainable continuous improvement culture that reduced operational costs while improving production reliability. The implementation of Performance Control Systems and Human Dynamics training enabled teams to identify and eliminate losses across multiple areas including oil, water and batter usage, equipment downtime, quality defects and maintenance cycles.

Savings realized in 8 months (€2.2M from Site 1 + €2.3M from Site 2)

Annualized savings planned (€2.6M from Site 1 + €3.9M from Site 2)

Workforce capability uplift (125 trained at Site 1 + 175 trained at Site 2)

Transformation Impact

- Established autonomous continuous improvement culture across two major production sites

- Reduced over usage of oil, water and batter in production processes

- Decreased unplanned equipment stops through improved cleaning, inspection and lubrication standards

- Minimized quality defects in final products

- Shortened cycle times by reducing sanitation and maintenance duration

- Trained central improvement team of young potentials to lead future changes

- Installed Performance Control System with shift handovers, Gemba walks and performance meetings

- Mobilized and trained site teams through Human Dynamics workshops and feedback training

Our Approach

- Designed two 6-month BOOST programs executed in 8-week waves

- Launched a boot camp to train the central young potentials team in EFESO tools and methods (e.g., PCS, HD, RCA, improvement routes)

- Conducted holistic analyses of PCS, OEE, material losses, bottlenecks, and Human Dynamics

- Transformed the client’s initial high-level business case into detailed, validated business cases per site

- Launched improvement teams supported by HD actions such as operator dialogues, role clarification, and feedback training

- Installed the PCS ecosystem (shift handovers, Gemba walks, performance meetings, KPI structure, responsibilities)

- Ensured intensive collaboration with site teams and weekly communication of progress

Ready to Build a Culture Where Improvement Never Stops?

- Transform your operations from reactive firefighting to proactive excellence

- Stop losing money to hidden inefficiencies and unplanned downtime

- Join leading manufacturers who’ve embedded sustainable improvement into their DNA