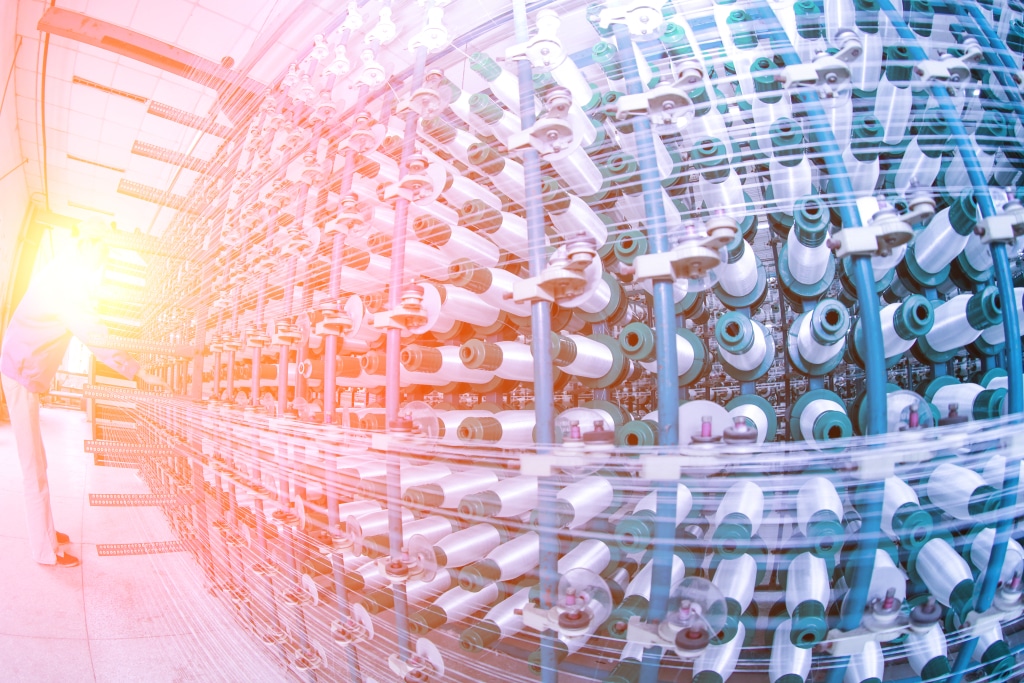

Productivity improvements through levelling, flow, and standard work.

Lean Lab Transformation in Pharma Boosts QC Productivity by 15%

A leading biotechnology company sought to accelerate Quality Control (QC) performance across its global biologics network. EFESO supported the transformation by deploying Lean Lab methodologies, improving productivity, standardizing processes, and ensuring reliable supply continuity.

Our Client

The client is a leading biotechnology company engaged in the discovery, development, and manufacturing of innovative medicines for patients with serious and life-threatening diseases. The collaboration focused on its biologics operations, encompassing both drug substance and drug product manufacturing within a global multi-site network across Europe, the United States, and Asia.

The Challenge

The project aimed to improve the speed, quality, and productivity of Quality Control (QC) functions at individual sites to ensure a more stable product supply. Additionally, it sought to develop a standard capacity planning tool and process to increase visibility of resources across sites and the global network.

- Low QC productivity: Need to release capacity and improve efficiency through standardization.

- Limited process visibility: Absence of an integrated capacity planning system.

- Inconsistent management practices: Lack of standard performance management and process control models.

- Global coordination challenge: Multiple sites operating independently without shared KPIs or improvement frameworks.

Real Results Achieved Together

The Lean Lab transformation delivered significant and measurable improvements in QC efficiency, resource visibility, and process stability. It enabled the deployment of standardized best practices across all sites and established a continuous improvement framework through visual management and performance governance.

Adherence to lead time targets

Year implementation duration

Transformation Impact

- Accurate projection of QC resource needs, highlighting capacity constraints.

- Implementation of a standard set of global QC KPIs linked to continuous improvement opportunities.

- Introduction of daily lab huddles supported by a standardized visual management system.

- Enhanced process control and performance visibility at both network and site levels

Our Approach

EFESO supported the client at both the network and site levels to establish standardized Lean Lab practices and build sustainable QC excellence.

At Network Level:

- Designed a standard visual management model to support daily process control and medium-term performance management.

- Developed a consistent capacity planning tool and process to forecast and balance QC resource needs.

At Site Level:

- Implemented levelling, flow, and standard work solutions tailored to various lab types.

- Deployed best practices in 5S and consumable management.

- Established daily lab huddles supported by a standard visual management system.

- Introduced global QC KPIs linked to continuous improvement routines.

Ready to transform your lab operations into a competitive advantage?

- Unlock 15 percent productivity gains while maintaining quality standards

- Stop struggling with capacity planning blind spots and resource constraints

- Join global pharma leaders who’ve standardized QC operations across multiple sites