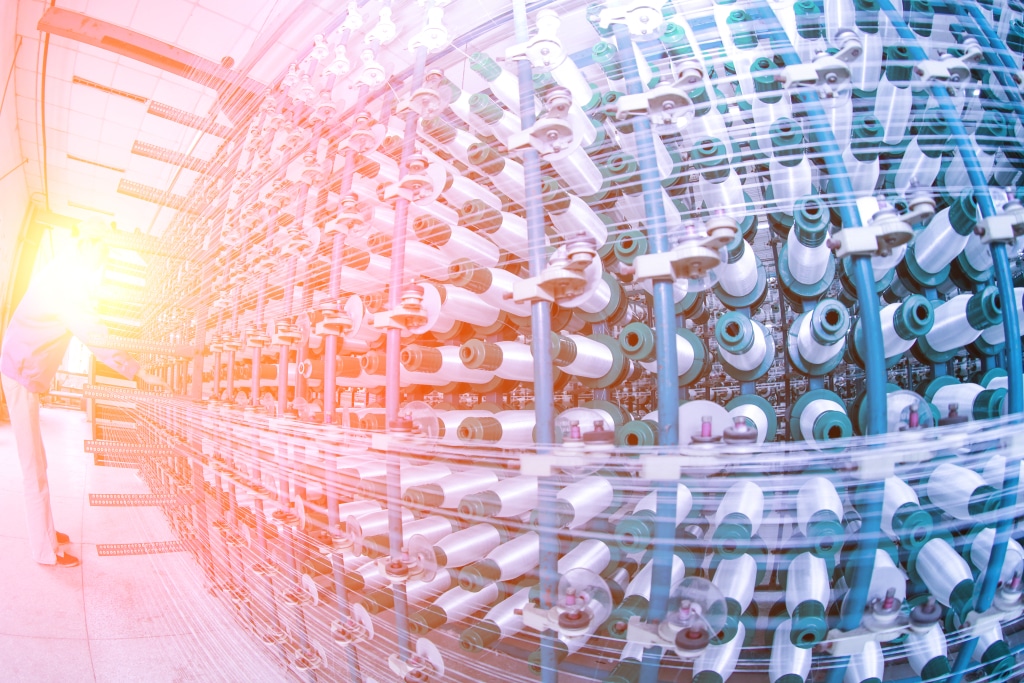

Production and R&D facilities

Optimizing Network Footprint to Offset Raw Material Costs and Enable Strategic Growth

A North American soil health innovator faced escalating raw material costs that threatened its competitive position. Working with EFESO, the company evaluated nine network configurations to identify optimal production and sourcing strategies. The transformation delivered $3.87M in annual savings while positioning the business for international expansion.

Our Client

This North American innovator specializes in proprietary humic and fulvic acid-based inputs that enhance nutrient uptake, water retention and crop yield for growers worldwide.

The company operates seven production and R&D facilities across North America, with a global reach. Following a recent change in ownership, the management team sought to redesign its supply chain and production network to prepare for international expansion and maintain its position as a leader in soil health solutions.

Current annual network cost

The Challenge

The company needed to tackle a fundamental shift in raw materials economics that threatened to undermine its entire cost structure. The immediate catalyst was anticipated price increases from its Canadian raw material supplier, with costs projected to rise from $139/MT to $240/MT.

This prompted management to evaluate strategic alternatives including:

- Raw materials sourcing options – Purchasing a mine, negotiating long-term supply agreements or reconfiguring its North American production and sourcing network

- Facility optimization pressures – Underutilized sites in the western US presented opportunities to consolidate production into higher-utilization locations

- Capability gaps – Plant 2 lacked the export and small pack capabilities essential for market expansion. This would require strategic upgrades to support growth while also needing to maintain cost competitive in an environment of rising material prices

Real Results Achieved Together

The network footprint evaluation delivered clear, data-backed insights that enabled informed strategic decision-making.

Together, we identified an optimal configuration that transformed cost pressures into competitive advantage while building in the flexibility required for future growth.

Annual cost reduction vs. baseline

Annual savings vs. current state

Alternative raw material cost achieved

Transformation Impact

- Established dual sourcing strategies providing flexibility to support multiple raw material options

- Created tactical roadmap balancing short-term wins with long-term investment options

- Positioned the business for continued domestic and international growth through optimized network design

Our Approach

EFESO applied a structured, data-driven methodology to evaluate the client’s network footprint. The approach began with comprehensive baseline modeling grounded in financial and operational data, including raw material costs from multiple sources, conversion ratios, freight and logistics costs, labor and utility expenses, capital expenditure requirements and plant-level capacity and utilization.

The team developed nine distinct network scenarios testing combinations of raw material sourcing strategies, including facility consolidation options, new plant construction near lower-cost raw material sources and upgrades to existing facilities. Each scenario underwent rigorous cost and investment analysis to evaluate total annual operating costs, capital investment required, payback period and strategic flexibility.

Through optimization and trade-off evaluation, the team identified Scenario 7 as the most cost-effective and strategically aligned option. This involved building a new facility near a low-cost raw material source, upgrading Plant 2 to handle small pack and export operations and consolidating production from Plant 1 into Plant 3.

Facing Similar Supply Chain and Cost Pressures?

- Struggling with raw material cost volatility while maintaining competitive pricing

- Seeking to optimize your production network without disrupting current operations

- Ready to transform operational constraints into strategic advantages through data-driven decisions