Continents involved

Product Cost Optimization for Automotive Thermal Management System

A leading automotive supplier faced mounting pressure to deliver cost-competitive thermal management modules while maintaining quality standards. Together, EFESO and the in-house team transformed a project that was previously delivering only a limited return on sales, achieving cost transparency across operations on three continents and exceeding targets.

Our Client

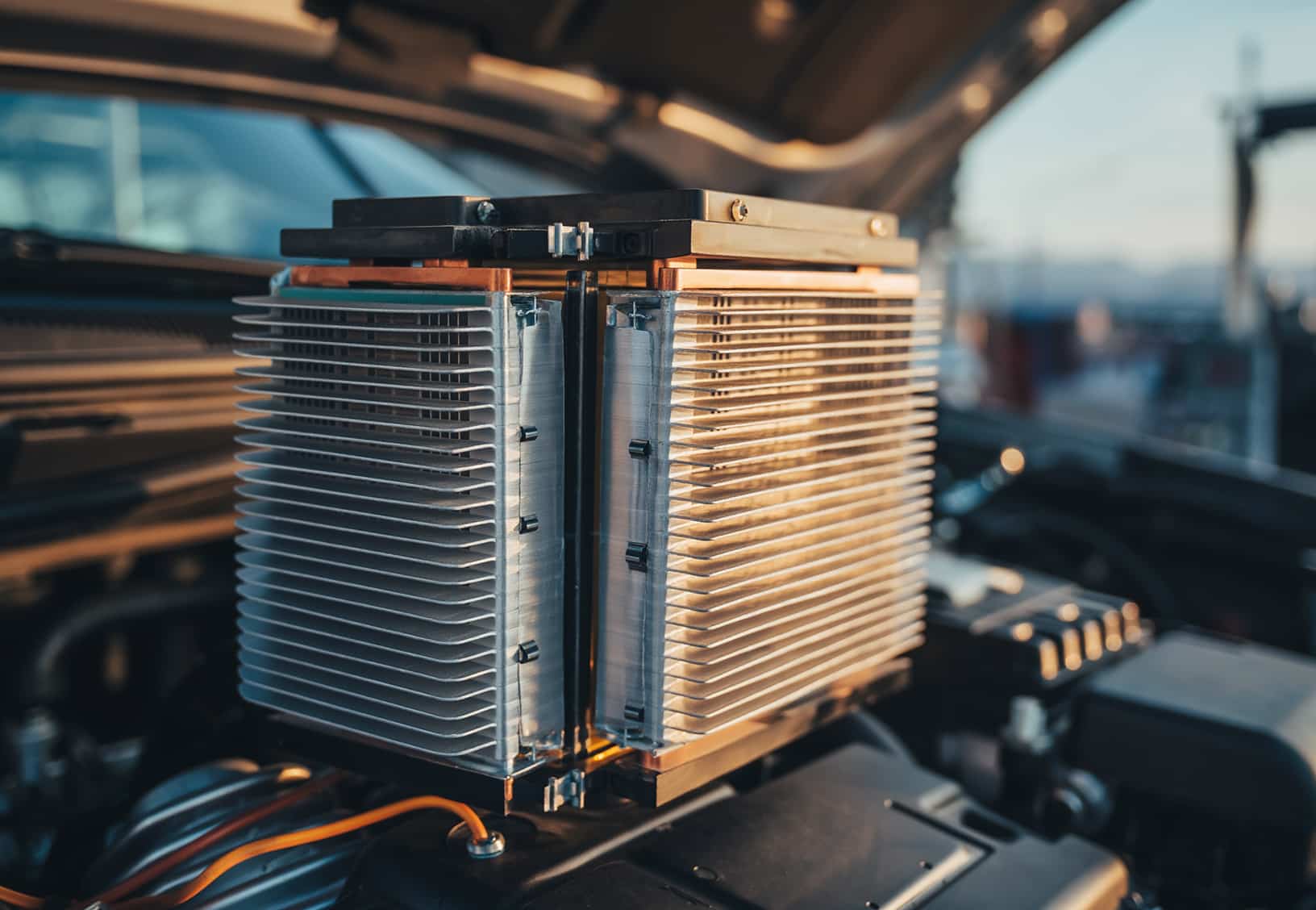

A global mechanical engineering company founded in the early 20th century, specializing in automotive components and systems. The company’s thermal and fluid systems business unit develops integrated modules for next-generation hybrid and electric vehicles. These innovative thermal management systems consolidate multiple subcomponents into single units, simplifying installation for OEMs while enhancing vehicle performance.

The Challenge

A thermal management system project faced critical profitability constraints and complex organizational dynamics.

- Multiple internal business units with differing interests complicated collaboration, as teams from engineering, purchasing, operations and finance brought unique priorities requiring extensive alignment sessions

- Global team distribution created significant coordination challenges, with R&D located in Germany, industrialization teams in North America and production facilities in Mexico, leading to communication barriers between time zones and languages

- The project was in a late phase, which intensified pressure. Only one year remained before the start of production, minimal redesign options were available and customer specification changes occurred frequently, requiring constant technical adaptations and real-time cost recalculations

Real Results Achieved Together

The comprehensive cost optimization initiative transformed an unprofitable automotive module project into a highly successful program. Working across multiple business units and continents, the collaboration established new benchmarks for cost management and cross-functional alignment.

Material and manufacturing savings indicated

Investment savings negotiated

Transformation Impact

- Established full cost transparency for purchased and in-house manufactured components, revealing critical discrepancies between controlling data and actual costs

- Implemented commercial and technical measures through systematic gap analysis, targeting high-impact components

- Created structured weekly reporting system enabling rapid issue resolution across globally distributed teams

Our Approach

The transformation began with classical product cost management. We performed a short costing analysis of the actual design, examining purchase parts, in-house components and capex to build a complete cost picture.

Component-level gap analysis identified the largest deviations between “should” costs and actual costs. Together with cross-functional teams, we initiated VAVE (value analysis and value engineering) activities and design-to-cost workshops, resulting in technical and commercial cost reduction measures.

The approach integrated expertise from cost and value engineering, purchasing, operations, manufacturing and capex teams. Weekly cost status updates tracked progress and identified roadblocks, particularly those arising from global team distribution. Bottom-up analysis of final assembly processes included detailed time-and-motion studies and cost simulations for material substitutions.

This comprehensive integration across all cost areas enabled the team to focus on high-impact savings opportunities rather than dispersed small improvements.

Facing Similar Automotive Cost Challenges?

- Struggling with unprofitable projects despite strong market demand and technical capabilities

- Seeking to transform cost structures while maintaining quality standards and compliance requirements

- Ready to build operational excellence through integrated cost management and cross-functional collaboration