Global engineering sites

Reducing Costs and Enhancing Collaboration Across Global Engineering Sites

A German heat exchanger specialist faced mounting price pressure from Asian competitors, as well as needing to manage three distinct engineering cultures across its global sites. Together, we broke down internal barriers and developed best practices across its Germany, Hungary and US operations. This transformation unified decades of diverse approaches to engineering design to deliver critical product cost reductions and streamline future cross-company collaboration.

Our Client

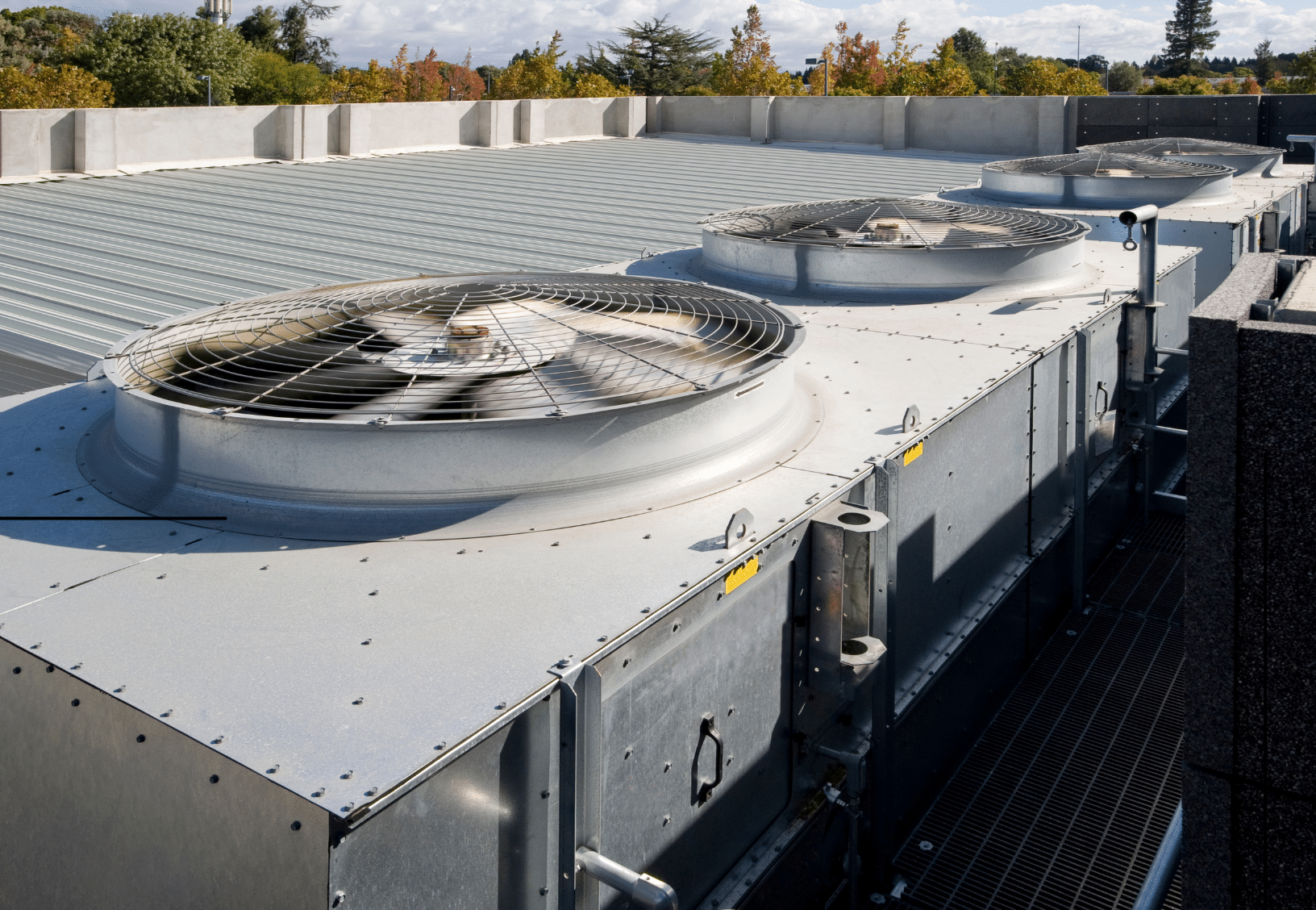

This mid-sized German industrial company specializes in custom-designed heat exchangers and cooling towers for power generation. Operating engineering and production facilities across multiple continents, the company was built on a heritage of German manufacturing excellence. Each installation is unique, based on location, temperature requirements and operational parameters–making every project a custom engineering solution.

Annual revenue

Production facilities worldwide

The Challenge

Increasing competition from China and Korea, and aggressive pricing on comparable products, threatened the company’s market position.

- Fragmented engineering practices: Each of its three locations maintained distinct design practices tied to different products and solutions, with engineers protective of their own designs and skeptical of contributions from other locations

- Custom complexity barriers: Each installation required a unique solution, with no standardized designs. This created further resistance to knowledge sharing and was preventing economies of scale across the organization

- Margin pressure acceleration: A combination of lower-cost competitors and internal inefficiencies in product design and manufacturing processes created an urgent need for integrated cost reduction, while maintaining customization capabilities

Real Results Achieved Together

The value engineering initiative transformed fragmented engineering operations into a collaborative network that preserved customization capabilities and helped to achieve significant cost reductions. This comprehensive program also established stronger cross-site collaboration processes and integrated best practices from each location.

Reduction in overall system costs

Project cost reduction achieved

Months transformation timeline

Transformation Impact

- Established knowledge transfer mechanisms through cross-site workshops that standardized engineering methods while respecting individual site contributions

- Achieved shop-floor efficiency improvements through process streamlining based on shared learnings

- Maintained competitive positioning through improved organizational alignment and collaborative practices

Our Approach

The engagement centered on the VE 360 (value engineering 360-degree) methodology, beginning with diagnostic assessment and baseline mapping of the product portfolio and design processes across all sites. We divided all product groups into sub-systems–heat exchanger bundles, piping, ducts and tanks, electrical controls, steel and FRP structure–which were re-designed to reduce costs and define global standards.

Design commonality workshops brought multidisciplinary teams from each office together, with meetings rotating across all three locations to foster mutual respect and understanding. Each site presented its approaches during process benchmarking sessions, exposing best-in-class ideas and surfacing areas of redundancy. Standard design concepts were defined for all regions with options for local requirements, helping the organization to work better across regions and functions. Implementation included consensus-driven adoption of harmonized processes, balancing global standards with any necessary customization.

Facing Similar Global Engineering Challenges?

- Struggling with cost pressures and managing multiple engineering sites with different working practices

- Seeking to harmonize global operations without losing local expertise and customization capabilities

- Ready to transform fragmented engineering cultures into collaborative excellence that delivers measurable cost reduction