Employees worldwide

Unified Performance and Culture Transformation Across a Global Food Network

Rapid growth and acquisitions created fragmented structures, cultures and processes across Bell Food Group’s extensive network. Together with EFESO, the company launched the “TopX” program—an enterprise-wide transformation unifying leadership behaviors; enabling Bell Food Group to sustain delivery performance above 98.5% despite rising costs and market complexity.

Our Client

Bell Food Group (BFG) is one of Europe’s leading food manufacturers and Switzerland’s largest provider of meat, poultry, seafood and fresh convenience products. Founded in 1869 and headquartered in Basel, the company operates multiple business divisions supported by corporate functions and decentralized operating structures positioned close to customers and markets.

Production and distribution locations

Net sales in 2024

“The close, partnership-based, and long-term collaboration with EFESO has been a key contributor to the success of this program.

“

The Challenge

As Bell Food Group expanded rapidly through organic growth and multiple acquisitions, operational diversity increased across the network. This complexity surfaced critical organizational challenges:

- Fragmented structures and cultures: Different leadership styles, legacy tools and non-standardized processes impeded alignment

- Decentralized decision-making: Local autonomy limited the ability to harmonize priorities and practices groupwide

- Rising competitive and regulatory pressure: Sustainability, animal welfare, food safety and cost inflation intensified execution demands

- Talent and capability asymmetry: Varying maturity levels in industrial excellence affected performance consistency

- Supply chain and delivery pressures: Networkwide growth introduced visibility, planning and performance risks

To achieve its ambition of becoming a recognized “Leader in Food,” Bell Food Group needed a unified operational model and a common cultural foundation.

Real Results Achieved Together

The “TopX” program established a shared management and production system across Bell Food Group, aligning operational practices while embedding leadership routines and a common language throughout the enterprise.

Delivery readiness level consistently maintained despite inflation, sustainability investments and 12% volume growth

Employees actively involved across sites and functions

Improvement initiatives executed across the network

Transformation Impact

- Awarded “Best in Class” management system recognition by the University of St. Gallen

- Unified language, leadership approach and performance routines across all business units

- Operational excellence embedded in Bell Food Group’s DNA, improving consistency and execution discipline

- Strategic alignment achieved between corporate ambitions, divisional priorities and site-level actions

- “TopX” recognized as a talent accelerator, strengthening leadership readiness and internal career mobility

Our Approach

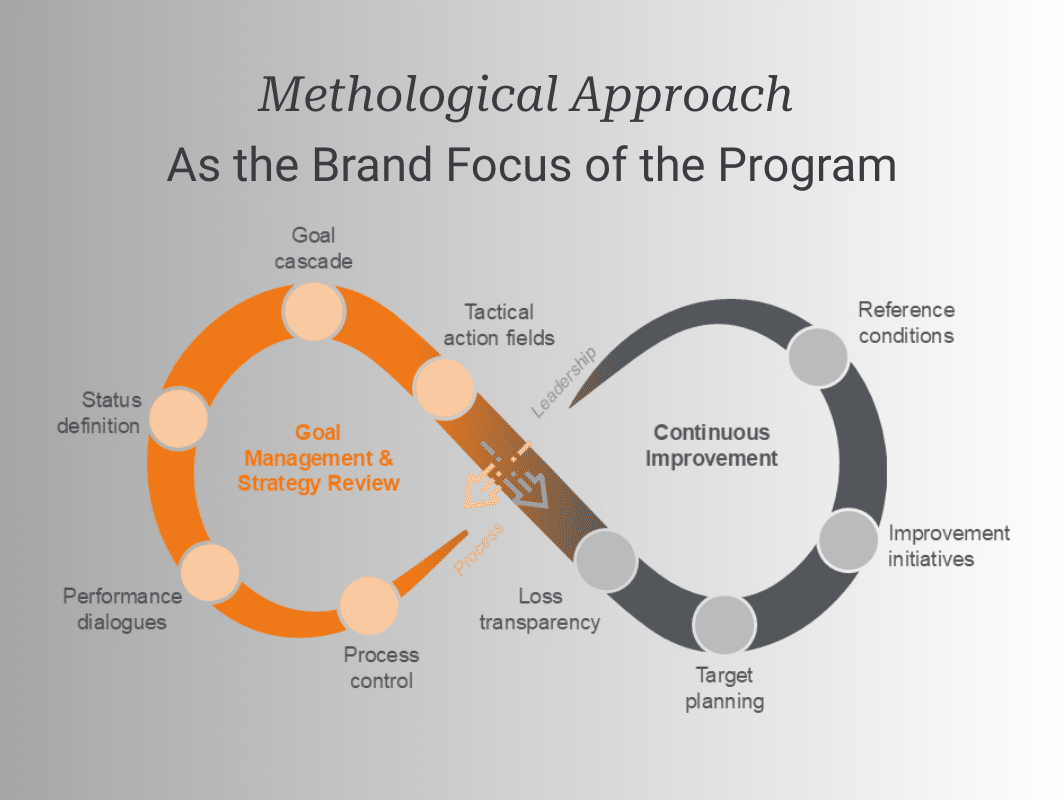

The approach connected strategic ambitions at corporate level with daily execution at site level, ensuring alignment across all business units and functions.

The transformation unfolded through a structured, multi-year journey:

- Leadership mindset and routine deployment: Management routines were introduced to create discipline, accountability and closed-loop performance monitoring. Leaders were coached to practice visible, engaged leadership on the shop floor

- Operational excellence practices scaled across the network: A harmonized improvement toolbox—including problem-solving, loss analysis, performance reviews, and shopfloor management—was rolled out and embedded across sites

- Capability building and coaching: Skills development programs, strengthening internal capabilities to sustain excellence without external dependency

- Governance and visual performance management: A single visual language, groupwide KPIs, and scorecards enabled cross-site benchmarking, transparency, and best-practice replication

This structured approach transformed TopX from a corporate initiative into a self-sustaining system—now embedded in Bell Food Group’s identity, leadership expectations, and day-to-day operations.

Facing Similar Multi-Site Operational Challenges?

- Struggling to harmonize processes and cultures across acquired sites

- Seeing performance variability across plants due to fragmented systems and leadership practices

- Ready to institutionalize operational excellence as a core identity rather than a project