Faster ramp-ups

Secure your Battery Factory's Industrialization

The battery industry faces intense operational pressure as gigafactories are set up amid rapid technological shifts – LFP, NMC and now solid-state chemistries. Capital is committed, timelines are tight and the stakes are rising. With global capacity projected to exceed demand by 2030 – putting pressure on plant utilization, pricing and long-term profitability – only the most streamlined producers will secure long-term positions.

Scaling from pilot lines to gigafactory operations requires technology and operational transformation. Together with your teams we will stabilize gigafactory ramp-ups – drawing on experience from over 22 battery engagements where we have reduced ramp-up time by up to 40%, controlled scrap through better process capability and embedded traceability into operations.

Real Results Achieved with our Clients

Battery manufacturers achieve scale through established expertise. Together with your teams, we turn operational complexity into a source of competitive strength – balancing production needs today with the agility to navigate in the evolving battery market.

Cost reductions

A Tailored and Pragmatic Approach that Fits your Reality

Battery strategies are often built on incomplete data, risking billions in capital misallocation. Industrializing a gigafactory demands more than technology – it also requires deep operational know-how and cross-functional coordination across materials, cell systems and manufacturing building blocks. At EFESO, we support you in industrializing your battery material, cells, system, or machinery production – from strategic investment to production ramp-up and operational stability. We apply a proven three-step approach:

- Check – Conduct due diligence and benchmark existing models

- Simulate – Stress-test scenarios and identify critical risks

- Deliver – Bridge product, production and investment expertise to ensure scalable execution

We support you in building a flexible plant, where both form factor and chemistry are key when dealing with frequent technology changes.

We focus on CapEx optimization – a way to optimize total cost of asset ownership.

We implement state-of-the-art integrated business planning concepts (IBP) throughout the supply chain.

We deliver a vertical start-up (VSU) methodology that allows you to ramp-up quickly to full customer requirements.

We help with the implementation of your digital maintenance transformation to improve OEE and yield.

We help you identify what needs to be considered when creating a financial model that will inspire confidence in the financial community.

FLEXIBLE VALUE CHAIN

We support you in building a flexible plant, where both form factor and chemistry are key when dealing with frequent technology changes.

Target & Results:

- Realization of a state-of-the-art battery

- Gigafactory with advanced manufacturing technologies, efficient production, logistics, and material flows, all while adhering to sustainability guidelines

FACTORY AND FOOTPRINT SETUP

We focus on CapEx optimization – a way to optimize total cost of asset ownership.

Targets and Results:

- Up to 50% increase in CapEx savings

- Up to 40% increase in CO2-e reduction

- Up to 25% optimization of the ROCE

SUPPLY CHAIN RESILIENCE

We implement state-of-the-art integrated business planning concepts (IBP) throughout the supply chain.

Targets and Results:

- Up to 20% improved forecast accuracy

- up to 2% increase in customer service levels

- up to 40% reduction of Inventory write-downs

- up to 1.5% reduction in excess manufacturing & service costs

SOP (start-of-Production) READY

We deliver a vertical start-up (VSU) methodology that allows you to ramp-up quickly to full customer requirements.

Targets and Results:

- Up to 20-40% reduction in time from SoP to full production

- 2x improved predictability (from 50% to 95% on-time delivery)

- 10-25% reduction in total project costs

Equipment Performance

We help with the implementation of your digital maintenance transformation to improve OEE and yield.

Targets and Results:

- up to 30% increase in Overall Equipment Effectiveness (OEE)

- up to 30% reduction in fixed maintenance costs

- up to 35% improvement in Wrench-Time

- up to 20% increase in MRO material availability

Capital Attractiveness

We help you identify what needs to be considered when creating a financial model that will inspire confidence in the financial community.

Our Services to Support your Transformation

Explore how our actionable, high-impact and tailored service offerings help you succeed

The EFESO Touch

To address the challenge of industrializing battery factories, EFESO’s battery excellence team ensures our work with you is grounded in solid analysis, robust data and operational reality. We’ve developed the world’s leading financial model for evaluating battery investments and our proven track record in turnkey factory implementation makes us a trusted partner.

Whether you are shaping a concept, preparing an investment case or launching a gigafactory, we bring unique expertise across new product introduction, manufacturing and industrial investment. Using benchmark-based financial models, we help strengthen the reliability and performance of your operating model, reducing risk and improving ROI.

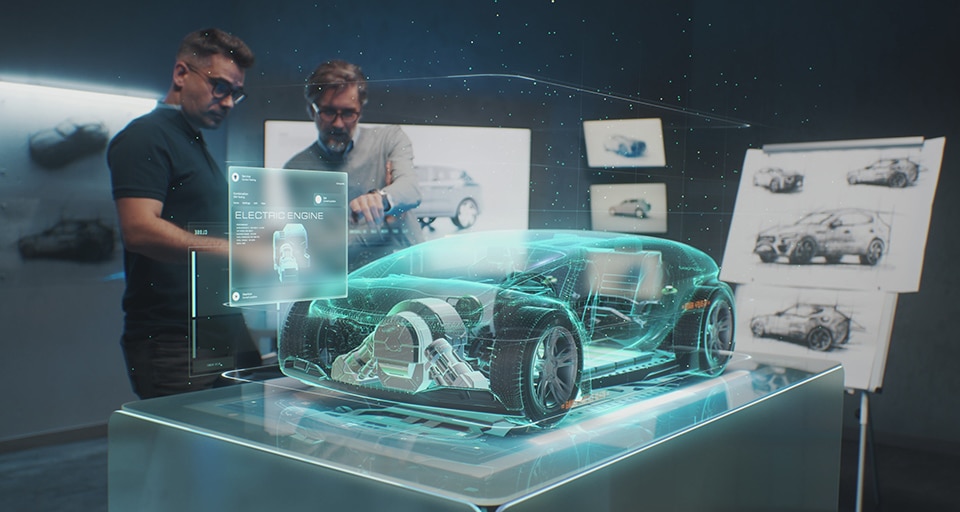

Our teams work hands-on with yours to address real issues, from cell formation bottlenecks to pack assembly. Together, we implement digital twins and train AI-based quality systems that embed performance into your operations.

Ready to Power the Battery Revolution?

- Scale from pilot to gigafactory without missing a beat

- Stop choosing between speed and quality

- Join manufacturers achieving 95% yields at scale