Andrea Montermini

Managing Partner EMEA

From May 2nd to May to May 5th was held the Motor Valley Fest in Modena, a pivotal gathering for automotive industry leaders, showcasing a mix of heritage and cutting-edge technology. An event where industry veterans and innovators converge to forecast trends and tackle the pressing challenges of mobility.

EFESO Management Consultants had the opportunity and privilege to be part of this major automotive event by participating to a panel discussion on “sustainability: LCA, ESG and materials”. Andrea Montermini and Andres Hernandez, alongside experts of the industry shared their experience from partnering with automotive companies to align their business goals with sustainability initiatives. Here are the main highlights from the session.

One of the greatest challenges our planet faces is climate change, exacerbated by greenhouse gas emissions from human activities. These emissions continue to worsen the problem, prompting companies to implement sustainability programs. In the automotive sector, decarbonization has become the key priority in sustainability strategies, affecting sustainability ratings, market capitalization, and brand reputation. Passenger vehicles, a significant contributor to global greenhouse gas emissions at 16%, are a key focus within the transport sector. Across the global economy, sectors face the substantial challenge of aligning their operations with the goals of the Paris Agreement on climate change. By 2050, automakers are expected to reduce CO2 emissions by 90%. It is becoming increasingly evident that solely electrifying the automotive industry may not be enough to meet the decarbonization objectives outlined in the Paris Agreement.

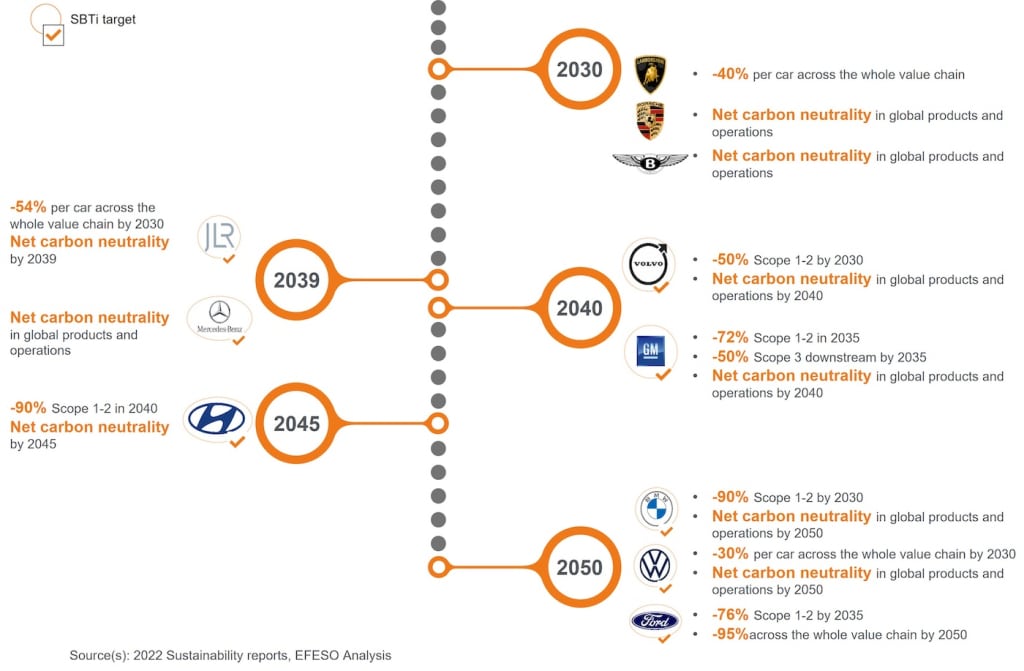

At present, most car manufacturers are embracing a target-setting process that aligns with the goals of the Paris Agreement. The targets set are very different among the top players. Ferrari, Lamborghini, Bentley and Porsche communicated challenging target already by 2030. Bentley for example is aiming for net carbon neutrality un global products and operations. Those targets are grounded on very different maturity levels in terms of solidity and thoroughness of reporting.

Getting automakers on track requires implementing a broad set of decarbonization levers.

While electrification stands as a cornerstone of the Net Zero roadmap for the automotive industry, its efficiency varies, especially for small-volume Original Equipment Manufacturers (OEMs). While it significantly reduces Scope 3 Downstream emissions by 50-70%, translating to a notable decrease in Product Carbon Footprint by 30-50%, it alone may fall short of achieving comprehensive decarbonization objectives.

Suppliers play a pivotal role in shaping the sustainability profile of vehicles by providing crucial components, materials, and technologies. Collaboration between OEMs and suppliers is particularly paramount to sourcing sustainable materials and tackling Scope 3 emissions effectively. For them, forging strong partnerships with suppliers emerges as a top priority to achieve ambitious decarbonization targets. This collaboration encompasses not only the adoption of environmentally friendly materials and processes but also joint innovation and research initiatives to develop cutting-edge solutions that minimize environmental impact across the entire supply chain.

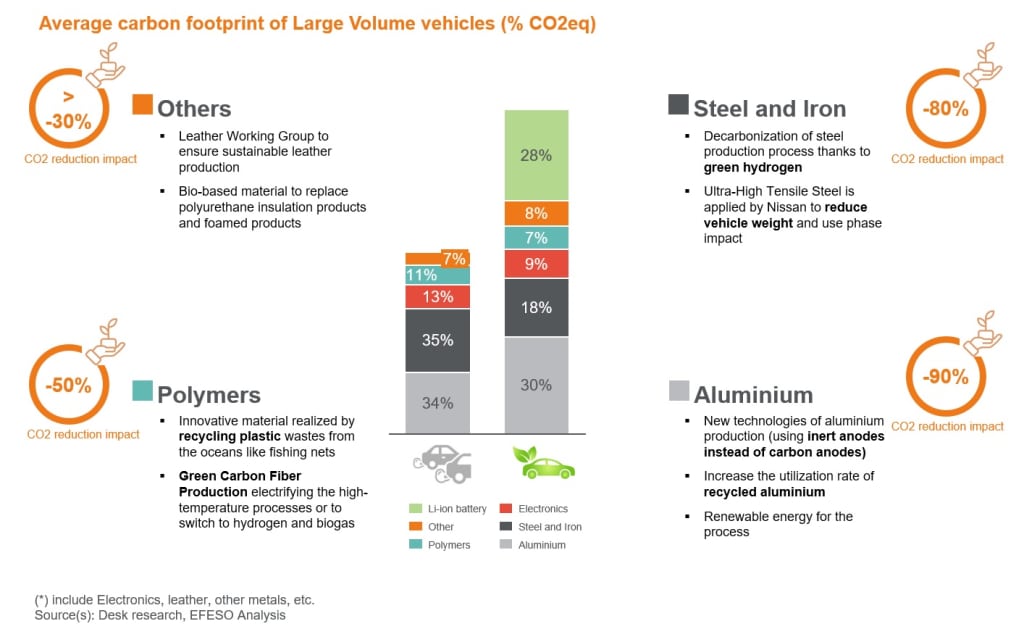

In Scope 3 upstream, decarbonization initiatives concentrate on implementing green processes and incorporating innovative and secondary materials into automotive manufacturing. These initiatives target the reduction of carbon emissions and environmental impact associated with the extraction, processing, and transportation of raw materials used in vehicle production. Furthermore, integrating innovative materials, such as recycled metals, bio-based plastics, and sustainable composites, enables the industry to reduce reliance on finite resources and minimize environmental degradation. Through concerted efforts to prioritize green processes and embrace alternative materials, the automotive sector can advance its decarbonization agenda while fostering sustainability across the entire value chain.

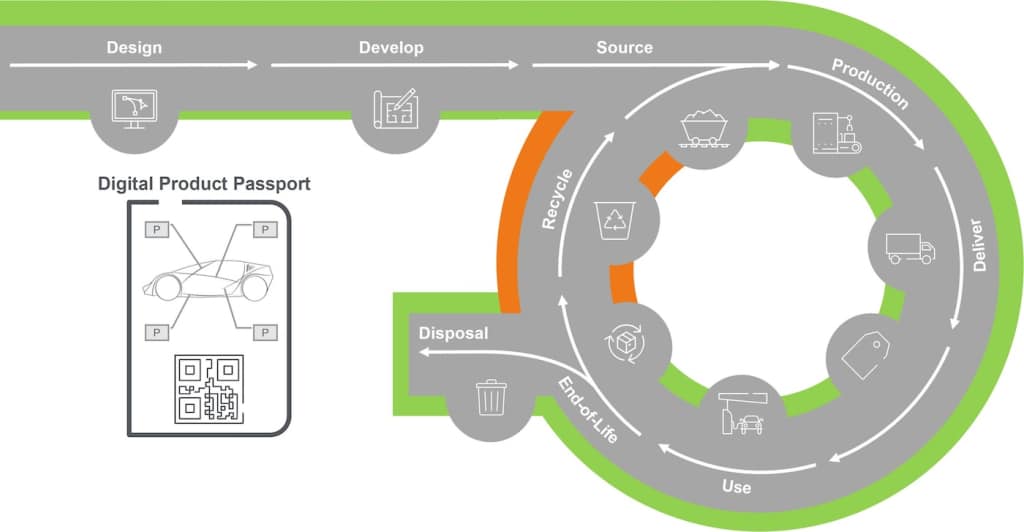

Advanced recycling processes offer a promising avenue for addressing Scope 3 downstream emissions in the automotive industry while unlocking significant economic benefits. By recovering valuable materials from end-of-life vehicles and waste streams, companies can minimize reliance on virgin resources, lower carbon emissions, and stimulate innovation. Embracing circularity principles and integrating digital technologies throughout the value chain can enhance the efficiency and viability of advanced recycling, facilitating material recovery and maximizing resource efficiency. Designing vehicles for recyclability, ensuring transparency in the supply chain, and optimizing end-of-life management processes are essential steps to realize the full potential of advanced recycling.

In the pursuit of automotive decarbonization, transparency and the establishment of standardized Product Carbon Footprint (PCF) and Life Cycle Assessment (LCA) methodologies are fundamental pillars for ensuring credibility, comparability, and guarding against greenwashing practices. It also promotes healthy competition within the automotive industry, incentivizing companies to innovate and improve their sustainability performance. These practices therefore contribute to building a more sustainable and trustworthy automotive industry ecosystem.

Discover more about Motor Valley Fest: Motor Valley Fest 2024 | Motor Valley

Managing Partner EMEA