Navigating Pressures on All Fronts

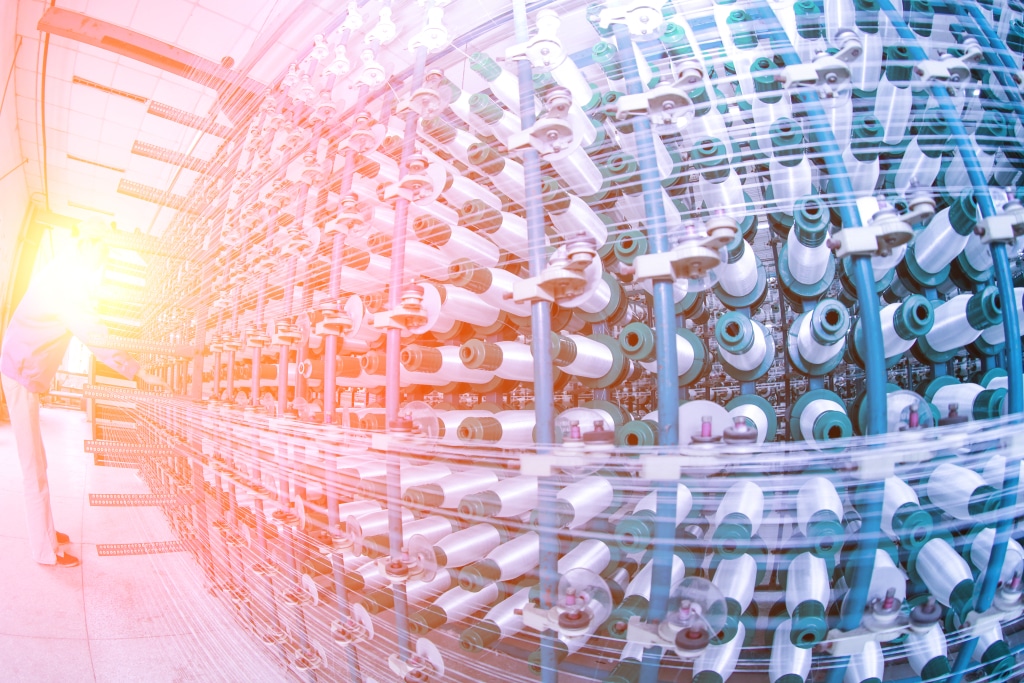

Consumer goods and luxury companies face pressure from all sides – where margin protection meets rising demands for environmental compliance. Manufacturing teams are asked to rethink long-established linear processes for circular models, all while absorbing steep increases in input costs. And when sustainable materials disrupt product specifications, reformulation and testing cycles lengthen, delaying market entry.

Fragmented supply chains add to the complexity. Limited visibility across multi-tier networks and reduced retail inventory make it difficult to react to and absorb volume fluctuations. What used to be systems built for efficiency must now evolve into agile and responsive networks, in partnership with suppliers and retailers, by adopting the right digital solutions

Real Results Achieved with our Clients

Our hands-on approach with consumer goods and luxury leaders turns operational challenges into competitive advantage. Here are some of the tangible results we've achieved together:

Cost reduction

Inventory reduction

CO2 emissions

A Tailored and Pragmatic Approach that Fits your Reality

Consumer goods companies navigate constant change, shifting preferences, sustainability mandates, and complex supply chains. Working alongside your teams, we turn these pressures into competitive advantage.

From optimizing production lines to embedding circular design principles , and from end-to-end loss eradication in partnership with your key suppliers and customers to design-to-value for CapEx reduction, we build lasting capabilities while delivering measurable improvements.

Our specialists combine deep CPG expertise with technology-enabled frameworks, creating resilient operations that respond faster to market demands while reducing costs and environmental impact. Together with your upskilled people, we turn operational constraints into your market edge.

Meet our Consumer Goods and Luxury Leaders

Start the conversation

Our Services to Support your Transformation

Explore how our actionable, high-impact and tailored service offerings help you succeed

The EFESO Touch

Our experience spans over 250 consumer goods and luxury transformations, delivering measurable impact. Seven of the top ten brands trust our hands-on approach.

Specialized in end-to-end operational excellence, we work with your teams to apply real end-to-end operations expertise, not presentations.

Meet Some of our Consumer Goods and Luxury Team Members

Ready to Crack the Consumer Code?

- Launch products that fly off shelves

- From supply chain complexity to seamless execution

- Join brands achieving 2x category growth