Watch the video

For Optimal Manufacturing Efficiency

Global security and technological disruption are reshaping the defense landscape. Across Europe, demand for military and defense drones is accelerating sharply, driving a new wave of industrial and manufacturing investment.

The market is expected to grow more than tenfold by 2034, creating an urgent need for efficient drone manufacturing capacity and future-ready factory design.

But while demand soars, production capacity lags. Building and scaling flexible, modular drone factories has become a strategic imperative for manufacturers aiming to lead this next phase of industrial growth.

The European military drone market is projected to grow from USD 7.95 billion in 2024 to USD 85.45 billion by 2034, a compound annual growth rate of 26.8%. Germany, the UK, and Spain are leading this expansion, supported by rising defense budgets and modernization programs.

This growth will require a tenfold increase in production capacity, with hundreds of new or expanded factories across Europe in the next decade. An average drone production site today operates with:

Setting up a drone manufacturing plant is complex. Companies face critical decisions at every stage:

Each decision directly impacts time to market, capital efficiency, and scalability.

Every COO faces the same challenge: how to industrialize innovation at the speed the market demands, without compromising cost, quality, or agility.

We have identified five key enablers that make a drone plant efficient and adaptable:

These enablers create factories that are technically and spatially standardized, flexible, and cost-efficient, supporting high performance and fast scaling.

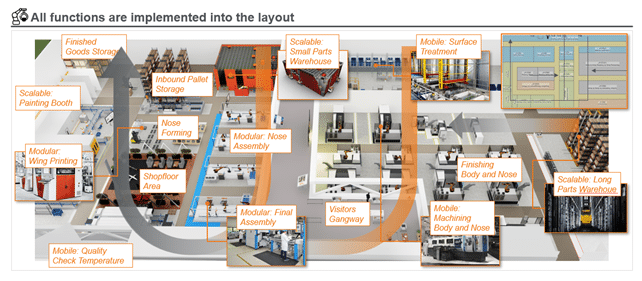

Traditional large-scale plants no longer fit the rhythm of this market. Tomorrow’s drone manufacturing model is modular, flexible, and connected. EFESO has developed a modular drone factory model that can be adapted to different operational contexts. This concept ensures agility, scalability, and reduced CapEx through modular design, digital integration, and sustainability principles. It supports fast response to demand, localized production, and controlled investment, with shorter realization times and optimized operating costs.

A blueprint for scalable, adaptable production ecosystems:

This isn’t a theoretical model. It’s a tested, digitalized factory concept, flexible enough to fit any manufacturer’s footprint, from pop-up assembly lines to full industrial campuses.

Example configuration:

Each module integrates automation, digital backbone, and efficient material flow, with production arranged for minimal distance and maximum throughput.

EFESO supports drone manufacturers through every stage of factory realization, from initial strategy to operational ramp-up.

Our ‘Future Factory’ toolbox covers:

This end-to-end approach ensures shorter lead times, optimized CapEx/Opex, and fast operational stability.

EFESO touch: We don’t just design factories. We make them work. EFESO combines strategy, factory design, and ramp-up execution in one integrated approach.

Those who can build smarter, faster, and more flexible factories will lead it.

EFESO brings the industrial and operational expertise to make that transformation happen, from blueprint to ramp-up.

By combining strategy, factory design, and ramp-up execution in one integrated approach, we don’t just design factories with you, we make them work.

Send us an email at customer.service@efeso.com