Increase in productivity

From Efficiency Gains to Strategic Resilience: The New Demands on Operations

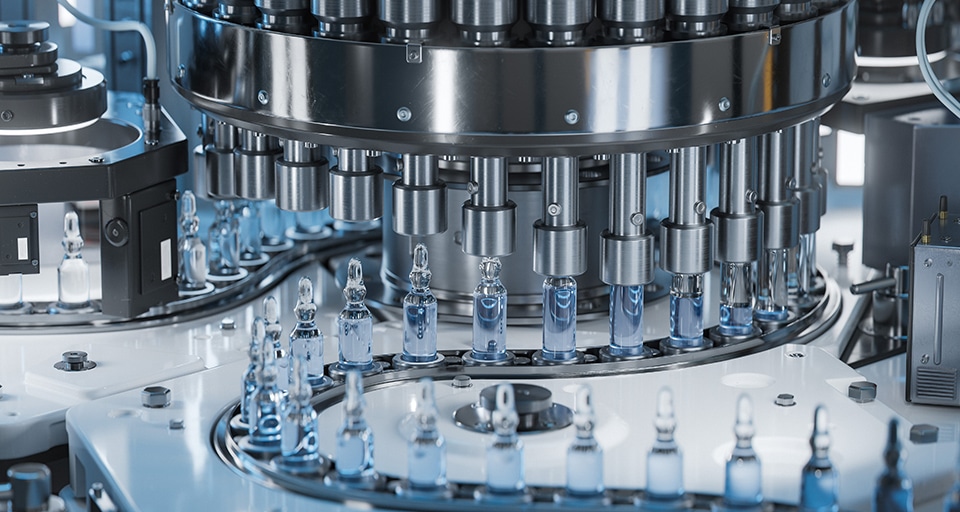

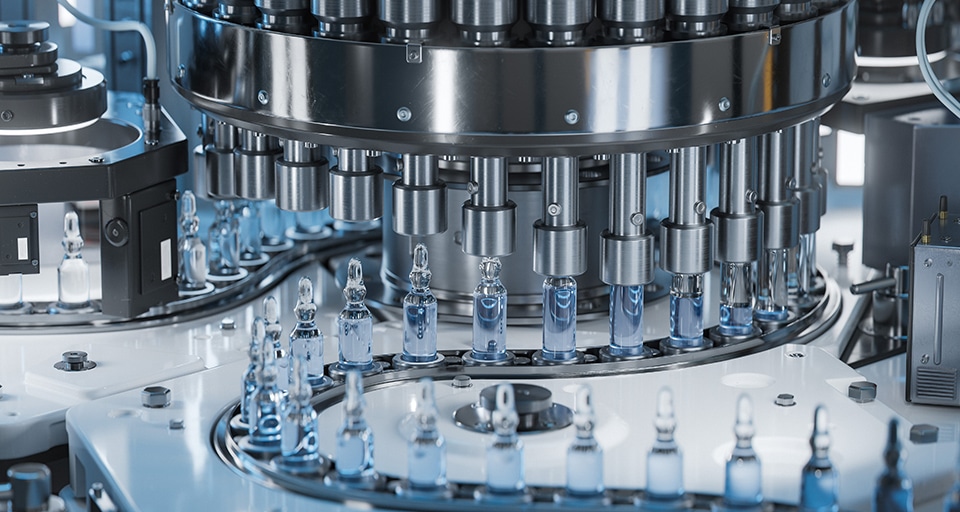

In an ever-changing business environment, it is crucial to continuously review and adjust operational strategies to ensure high service levels and team efficiency. Manufacturing leaders are under pressure to increase volumes, improve quality, remove bottlenecks from their production lines, and on-time-in-full delivery reliability, while reducing costs and strengthening resilience. Yet many programs fail to deliver their full potential, as local sites pursue fragmented approaches or plateau improvements.

Operational Excellence is evolving from mere cost reduction to fostering new business models across the supply chain, including circular economy practices and Product-as-a-Service offerings. At the same time, digitalization and automation are transforming core methods and roles, while talent shortages and compliance requirements create additional complexity.

Without decisive transformation, companies risk stagnation and missed opportunities. EFESO helps organizations overcome these barriers by transforming operating systems and cultures, embedding excellence that boosts performance today while preparing for tomorrow’s competitive and regulatory challenges.

Meet our Operational Excellence Leaders

Start the ConversationReal Results Achieved with our Clients

Some of the tangible results we achieve with clients in operational excellence programs:

Increase in OEE (Overall Equipment Effectiveness)

Decrease in conversion cost

A Tailored and Pragmatic Approach that Fits your Reality

EFESO delivers sustainable performance improvements by combining operational excellence foundations with advanced digital transformation. We start by analyzing processes, systems, and behaviors to identify improvement priorities, then co-design a transformation roadmap aligned with strategic objectives. Implementation happens side by side with client teams, ensuring knowledge transfer and lasting ownership. This combination delivers rapid impact while embedding a culture of operational excellence across sites and organizations. Whether accelerating performance at a single site, rolling out global programs, or designing smart factories, EFESO helps you unlock the full potential of your operational excellence program.

Is your operational performance no longer progressing, or only improving through Capex?

Does your business need to create a single standardized way of working across the organization?

In manufacturing, incremental change is constant. Yet many businesses eventually reach a point where incremental improvements no longer deliver world-class excellence.

Is your business in urgent need of stronger operational performance to meet volume demands?

Is your business running an Operational Excellence program but dissatisfied with the impact of middle management?

Process Kaizen Engineers: the future leaders of the operations world

Operational Excellence at Site Level

Is your operational performance no longer progressing, or only improving through Capex? This might be the right moment to implement or renew your Operational Excellence approach. We have supported multiple factories worldwide in achieving recognized excellence.

Built on the zero-loss principle, WCOM™ works at three levels: loss intelligence, loss eradication, and loss prevention. By identifying all losses and their value, applying the right tools to eliminate them, and building systems to prevent recurrence, organizations achieve sustainable performance improvements. Step by step and hand-in-hand with your teams, we create a truly embedded and future-proof approach.

Our operational excellence approach – enriched with AI and the latest digital use cases and combined with change management, leadership, and performance behaviors – drives immediate results today and secures results for tomorrow by developing the capabilities of people, processes, and systems.

Operational Excellence at Company Level

Does your business need to create a single standardized way of working across the organization? EFESO has applied its globally standardized World Class Operations Management (WCOM™) approach across multiple industries, consistently improving business performance. Every EFESO consultant masters this approach, enabling us to work in a uniform way worldwide.

Our programs begin by aligning objectives with company strategy, forming the basis for a group-wide roadmap. Typically, we start with pilot sites, then roll out across the network, supported by toolkits in local languages and tailored training academies. After a short assessment phase, with clear targets and a master plan to achieve them, implementation is closely monitored to ensure progress.

Integration of change management, leadership development, and digital tools drives results for tomorrow as well as today – making this a truly embedded and sustainable approach to Operational Excellence.

Design for Operational Excellence

In manufacturing, incremental change is constant. Yet many businesses eventually reach a point where incremental improvements no longer deliver world-class excellence. At that stage, a major change of the operating system may be needed: a different factory setup, a redesigned organization, or a new approach to maintenance management.

Design for Operational Excellence helps define and implement these fundamental changes. We identify upcoming challenges, assess the “as-is” situation – including processes, factory layout, organization, leadership, and technology – and design the required “to-be” operating system. The gap between the two is translated into a business case and supported by a clear implementation roadmap.

To firmly anchor results, we begin with a change-readiness check to identify key responsibilities and stakeholders. EFESO experts guide you throughout – from assessment and design to sustainable implementation.

Operational Performance Improvement

Is your business in urgent need of stronger operational performance to meet volume demands? Do you need to improve quality, enhance service, or reduce costs and boost productivity in the short term?

EFESO has the approach to deliver rapid improvements by assessing critical workstreams and installing clear performance management practices, roles, and responsibilities – supported by leadership development and performance behaviors. With structured project management, clear milestones, and deliverables, measurable results are visible within three to six months.

Because our programs integrate human dynamics, these short but intensive interventions deliver not only immediate gains but also sustainable long-term impact. This approach can be applied to production, maintenance, quality, or across entire facilities, breaking down silos that otherwise limit site-wide improvement.

Leading Performance

Is your business running an Operational Excellence program but dissatisfied with the impact of middle management? Have leadership training sessions failed to translate into lasting performance improvements?

EFESO’s Leading Performance approach develops leaders from the shop floor to the boardroom, coaching them to lead performance both in the short and long term.

Our process begins by defining the desired leadership framework. From there, we select High Impact Moments (HIM) – such as daily factory meetings or Gemba rounds – and translate them into concrete behaviors. We then build leadership skills aligned with these moments and coach leaders to apply them consistently.

This program has been proven to create sustainable improvements in operational performance by embedding effective leadership practices across all levels of the organization.

Process Kaizen Engineers (PKE)

Process Kaizen Engineers: the future leaders of the operations world

To keep pace with today’s fast-moving technological developments, organizations must invest in building their own capabilities. This is especially true for roles that require a strong technical background combined with advanced leadership and managerial skills. Addressing this need, EFESO Management Consultants created – and continues to evolve – its Process Kaizen Engineers (PKE) Development Programs.

Facts and figures :

- Over 300 sessions delivered in blue-chip companies since the early 1990s

- More than 6,650 certified participants across 24 countries (including the United States, United Kingdom, Brazil, Germany, China, India, and France)

- More than 10,450 completed projects

- The return on investment of our PKE training program often exceeds factor 10

- Training costs typically recovered within three months

- Available in 22 languages

- Adopted by many clients as part of their internal qualification programs

Why start a PKE program?

A hands-on approach to rapid development

High-potential engineers and young managers receive deep training in essential theoretical and technical aspects of their roles. Topics include problem solving, maintenance, quality, focused improvement, Lean flow, sustainability, education and training, safety, and Industry 4.0.

The first phase of the program is highly practical, combining interactive learning, simulations, group Gemba[1] exercises, and coaching. This builds a strong common foundation for the second phase: the realization of a live project led by the participant within their own organization.

Implementing real improvement projects

The core of every PKE program is a live project with bottom-line impact. Each participant leads a project addressing a critical company issue – typically cost or lead-time reduction. Documented savings and a final project examination confirm the participant’s qualification as a Process Kaizen Engineer.

Because these projects generate tangible benefits, the program is effectively cash-neutral: the payback for the organization typically occurs within the first year.

An accelerated career

Graduates of the PKE program acquire a multidisciplinary mindset, developed by solving complex problems across processes, people, and technologies. The qualification is a career accelerator, as participants build strong networks and gain recognition at multiple levels of the organization.

Blended learning

PKE programs are also offered in blended-learning formats. Participants follow structured self-learning paths combined with online interactive sessions in which teams solve complex problems in virtual labs. These are complemented by in-person sessions, which are essential for testing understanding and applying skills. This blended model prepares participants for the live project phase – the critical step toward final PKE certification.

(1) Gemba: A Japanese term meaning “the actual place.” In lean practices, the Gemba refers to the place where value is created – for example, the shop floor in manufacturing. “Gemba walks” involve going to see the process, understanding the work, asking questions, and learning directly from those performing the work.

The EFESO Touch

What makes EFESO distinct is our ability to deliver results quickly while building systems that sustain progress. We work hand-in-hand with your teams, creating step-change improvements in productivity, quality, and service, while embedding the leadership behaviors and digital practices that secure long-term competitiveness. In an ever-changing business environment, it is crucial to continuously review and adjust operational strategies to ensure high service levels and team efficiency.

With 40 years of experience, EFESO integrates proven methodologies – such as WCOM™ (World Class Operations Management), TPM (Total Productive Maintenance), and Lean Six Sigma – with leadership coaching, human dynamics, and digital tools. Our WCOM™ framework – certified by the Japan Institute of Plant Maintenance (JIPM) – guides a structured zero-loss journey from loss intelligence to eradication and prevention. Whether boosting site-level performance, rolling out a global program, or redesigning an operating system, every initiative is rooted in your reality. We combine change management, leadership, and digital technology with strong capability to implement global programs and transfer rigorous Continuous Improvement practices.

Meet Some of our Operational Excellence Team Members

Ready to Make Excellence Your Default Mode?

- Build improvement into daily work, not special projects

- Stop sliding back after consultants leave

- See teams sustaining continuous gains year after year