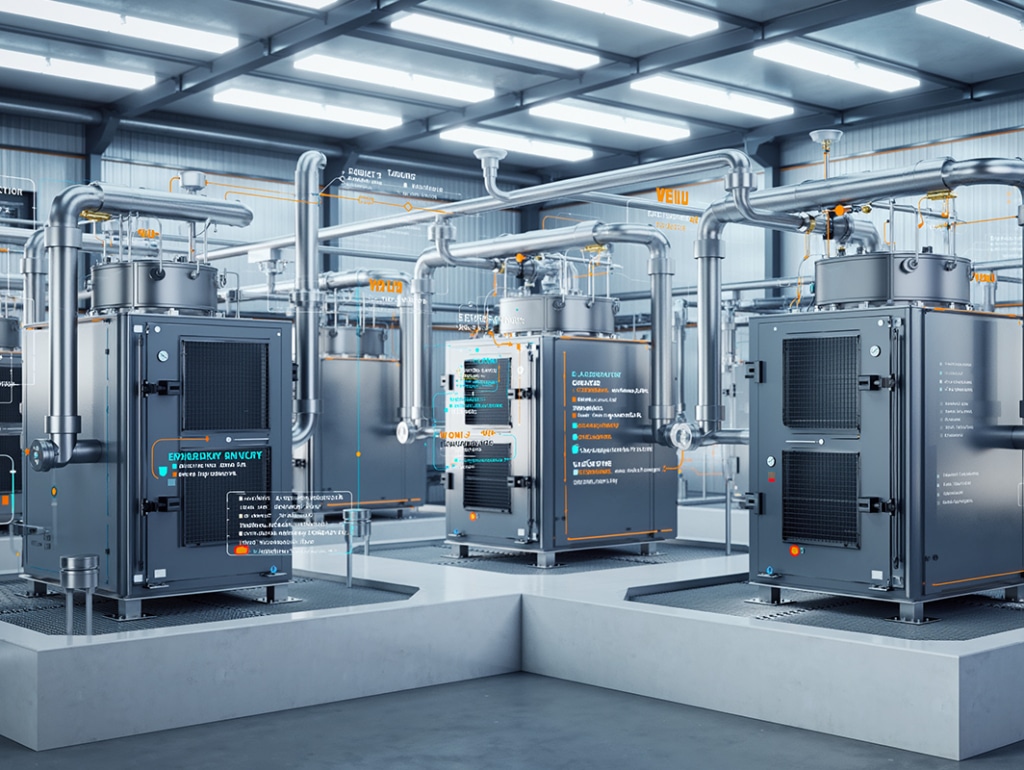

Transformed manufacturing operations for energy technology leader, doubling production output while identifying $16M EBITDA opportunities.

Discover how EFESO works side by side with clients across industries to achieve measurable, lasting impact. Each story captures the challenges our clients faced, the actions we took together – from boardroom to shop floor – and the tangible operational and financial results delivered.

Transformed manufacturing operations for energy technology leader, doubling production output while identifying $16M EBITDA opportunities.

Digitized operational excellence framework across 20 European sites, achieving 25% OEE improvement and multimillion savings.

Reduced military aircraft lifecycle costs by over 10% through design-to-cost analysis and supplier collaboration.

Rapid expansion strained jewelry supply chain. Comprehensive planning framework established. Enabled sustainable growth for 30,000+ employees globally.

Packaging manufacturer achieved €636K savings through optimized labor ratios, reduced scrap, and material efficiency improvements.

Chemical company restructured operations post-Chapter 11, implementing organizational redesign and maintenance excellence, achieving €6M annual savings.

Transformed unprofitable thermal management module through systematic cost optimization, achieving material, manufacturing and investment savings exceeding targets.

Equipment failures drove 50% productivity loss. Rapid mobilization restored three bakeries to profitability within nine months.

Transformed seven manufacturing facilities across three countries, achieving 30% productivity gains and 45% faster innovation.

Deployed global OpEx program across 25 plants, standardizing waste reduction practices to deliver €40M savings and 4.5M tons CO₂ reduction.

A global specialty chemicals leader harmonized maintenance across 17 major sites, achieving €50M+ in annualized benefits and developing a sustainable transformation infrastructure.

Integrated two heritage organizations through customized production system across 12 chemical sites, delivering €67M annual benefits.

Transformed industrial supply chain through lean operations and product simplification, delivering €15.5M savings and 10% service improvement.

A global cosmetics manufacturer sought to digitalize the Performance Control System used in its distribution centers, replacing paper-based boards that slowed communication and limited operator involvement.

Redesigned manufacturing organization across seven functions using Fit-to-Win methodology, delivering €4.5M savings beyond 10% target.

Embedding lean culture by linking performance and behavior across beverage sites, achieving 10% fewer safety incidents and $2m waste savings.

Assessed maintenance and reliability gaps at PVC producer's sites, delivering detailed improvement roadmap achieving 30-55% loss reduction.

Pharmaceutical manufacturer optimized three-factory footprint, postponing €300M investment while achieving 20% growth through strategic operations transformation.

Eliminated EV battery component press bottleneck through scientific process optimization, achieving 30% productivity gain and enabling future volume growth.

Streamlined biotechnology contract manufacturing operations, reducing 18-24 month lead times by 60% and inventory by 45%.

Developed comprehensive five-year business plan for European CRO, identifying 40% growth potential through strategic positioning.

Deployed World Class Manufacturing pilot across cosmetics plants, driving OEE from 55% to 70% through standardization.

Urea reactor failures slashed output by 50%. PM analysis traced root cause to upstream pump lubricant. Restored stable high performance.

Aligned pharmaceutical manufacturing footprint with 2030 growth targets, delivering €100M savings and 15% CapEx reduction.

Discover measurable outcomes achieved with our clients

See how transformation happens, from boardroom to shop floor

Let’s discuss how we can deliver similar impact for you