Discover how unprecedented demand and pressure are reshaping the UK Aerospace & Defence sector for the decade ahead.

Operations are at the center of business transformation. Every market shift, regulatory change, and digital advance creates new challenges, and new opportunities.

Through our insights, we share pragmatic perspectives rooted in hands-on project experience. Through events, we foster dialogue between executives, practitioners, and EFESO experts who are redefining what operations strategy and performance improvement means in practice.

This is where strategy meets implementation, where peers learn from each other, and where leaders find inspiration to act with confidence.

Discover how unprecedented demand and pressure are reshaping the UK Aerospace & Defence sector for the decade ahead.

The second EFESO edition of the AI Observatory in European Procurement signals a clear inflection point. In 2026, organizations are moving beyond broad experimentation toward selective industrialization of generative AI.

Transform sustainability from compliance burden into measurable value creation for private equity portfolio companies.

Automotive electrification disrupts traditional supply chains. EFESO quantifies impact across nine vehicle systems, revealing strategic repositioning imperatives for suppliers.

EFESO surveyed 150 manufacturing executives across North America to have a comprehensive view of the decisions shaping manufacturing’s future.

EFESO helps drone manufacturers build future-ready factories, modular, scalable, and digitalized, to meet fast-growing defense market demand.

The UK off-highway vehicle sector is experiencing rapid growth, driven by electrification, sustainability, and infrastructure expansion, presenting significant opportunities for manufacturers.

Aerospace and defense firms need agile, value-focused capital investment strategies to manage complexity and maximize performance.

Chemical supply chains face mounting cost pressures and geopolitical uncertainty requiring strategic footprint optimization and sustainability integration.

UK food, beverage, and consumer goods sectors face rising labor costs due to increased NI contributions and minimum wage, impacting profitability and competitiveness.

Discover how EFESO And SEAM empowered European abrasives manufacturers to measure and reduce their carbon footprint

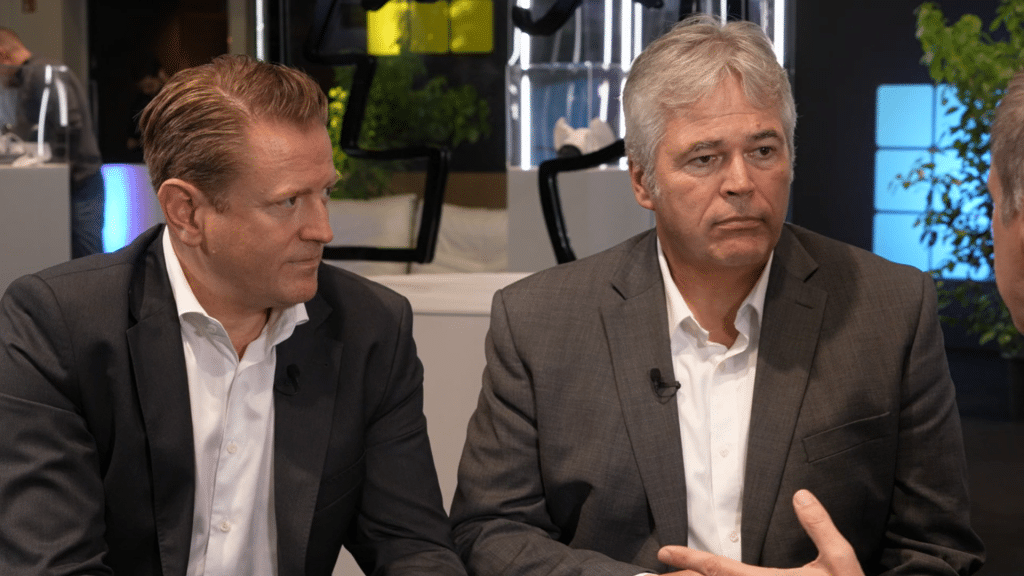

An interview with BBC StoryWorks on how leaders can remain effective in times of uncertainty by combining a clear sense of purpose with true operational agility.

Developed logistics strategy enabling Primark's multi-market expansion while integrating new distribution center technologies across channels.

Strategies and frameworks to help businesses stay competitive, agile, and resilient amid turbulent market conditions.

Transforming intelligence into competitive advantage through adaptive strategies, digital excellence, and smart production systems.

Stabilizing aerospace supply chains disrupted by pandemic and geopolitical tensions through dual-track operational and strategic interventions.

Transformed CapEx management by integrating lifecycle costs, CO2 emissions, and speed into strategic decision-making frameworks.

Discover seven proven factors from 1,000+ projects that drive sustainable EBITDA step-change improvements within 24 months.

Discover how supply chain leaders can avoid common APS pitfalls by focusing on data quality, process readiness, and change management for real results.

Surveying over 100 supply chain leaders, this report identifies key strategies and challenges shaping European supply chain transformation through 2027.

Transforming CapEx from cost burden to competitive advantage through integrated technical expertise and strategic alignment.

This survey on generative AI in European procurement offers valuable takeaways to boost efficiency and unlock strategic value.

Empower your workforce by fostering collaboration between humans and machines, shifting from top-down control to a more inclusive, connected approach in digital transformation.

Expert panel distinguishes change from transformation in OpEx, revealing eight critical factors for sustainable program success.

Explore how these insights apply to your business